Producing a baseball glove involves various costs. On average, it ranges from $30 to $100 per glove.

Baseball gloves are essential for players. They come in different styles, materials, and sizes. Each of these factors impacts the production cost. Materials like leather or synthetic fabrics, labor, and manufacturing processes all contribute to the final price. Understanding these costs can help you appreciate the value of a quality glove.

Whether you’re a player, a parent, or just curious, knowing the breakdown of these expenses gives insight into what goes into making a baseball glove. Let’s explore the elements that determine the cost of producing a baseball glove.

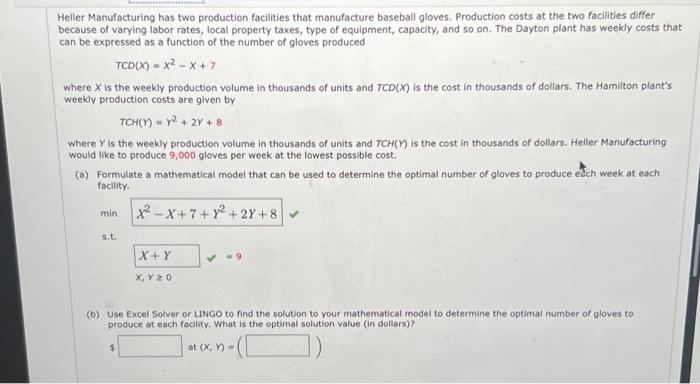

Credit: www.chegg.com

Materials Needed

Creating a baseball glove requires specific materials. These materials ensure the glove’s durability, comfort, and performance. Below, we’ll explore the essential materials needed to produce a high-quality baseball glove.

Leather

Leather is the primary material used in baseball gloves. It offers strength and flexibility. The type of leather can affect the glove’s cost and quality. Common types include cowhide, steerhide, and kip leather. Each type has its unique properties.

Cowhide is durable and affordable. Steerhide is tougher and more expensive. Kip leather is soft, lightweight, and offers a quick break-in period. The choice of leather impacts the glove’s performance and price.

Laces

Laces hold the glove together. They provide structural integrity. High-quality laces ensure the glove maintains its shape. Most laces are made from leather. They come in various thicknesses and lengths. Thick laces offer more durability. Thin laces provide more flexibility.

The lacing process requires skill. Proper lacing ensures the glove functions well. Poor lacing can lead to a glove that falls apart quickly. Investing in good laces is crucial for a long-lasting glove.

Padding

Padding is essential for player comfort. It protects the hand from impact. The padding material can vary. Common materials include foam, felt, and synthetic fibers.

Foam padding is lightweight and absorbs shock well. Felt padding offers a traditional feel. Synthetic fibers provide durability and moisture resistance. The amount and placement of padding can affect the glove’s fit and feel. Proper padding ensures a balance between protection and flexibility.

Labor Costs

Labor costs play a significant role in the production of baseball gloves. These costs depend on several factors, including the level of expertise required and the time spent on each glove. Let’s break down the details under various headings.

Skilled Workers

Producing a quality baseball glove requires skilled workers. These workers have years of experience. They know how to handle leather and stitching tools. Their expertise ensures each glove meets high standards. Finding and retaining skilled workers adds to the labor costs.

Hourly Wages

Hourly wages for glove makers vary. In some regions, the wages are higher. Workers in developed countries earn more. In developing countries, wages are lower. The cost of living in each region affects these wages. Higher wages lead to higher production costs.

Production Time

Producing a baseball glove is time-consuming. Each glove takes several hours to complete. The time depends on the complexity of the design. Custom gloves take longer to produce. Longer production times increase labor costs. Efficient processes can help reduce these costs.

Manufacturing Process

The manufacturing process of a baseball glove involves many steps. Each step ensures the glove meets the quality standards. Understanding these steps can give insights into the costs involved.

Cutting

The process starts with cutting the leather. Skilled workers use patterns to cut the leather pieces. These pieces will form the glove’s parts. Precision is key. Mistakes can waste material and increase costs.

Stitching

Next, workers stitch the cut pieces together. They use strong threads to ensure durability. This step requires attention to detail. Even stitches help the glove last longer. Special machines often handle this task. Each stitch adds to the labor costs.

Assembling

The final step is assembling the glove. Workers attach the stitched parts to form the complete glove. They add padding and insert the lining. This step also includes adding the laces. Quality checks ensure the glove meets standards. This thorough process impacts the overall cost.

Credit: www.nytimes.com

Equipment And Machinery

Producing a baseball glove involves several steps, each requiring specific equipment and machinery. Understanding the cost of these tools is crucial for estimating the total production cost. Below, we break down the essential equipment and machinery needed for making baseball gloves.

Sewing Machines

Sewing machines are vital for stitching the glove pieces together. Industrial sewing machines are preferred due to their durability and precision. A high-quality sewing machine can cost between $1,000 and $5,000. These machines often have specialized needles and threads designed for leather.

Some brands offer automated features, increasing efficiency. Automated sewing machines can go up to $10,000. Investing in a reliable sewing machine ensures consistent stitching quality.

Cutting Tools

Cutting tools are necessary for shaping the leather pieces. Hydraulic cutting machines are commonly used for their power and accuracy. These machines range from $3,000 to $15,000. Some manufacturers use laser cutters for more precise cuts. Laser cutters can cost between $10,000 and $30,000.

Manual cutting tools, like knives and shears, are also used. These tools are cheaper, costing around $50 to $200. However, they require skilled labor to ensure precision.

Maintenance Costs

Maintenance is essential to keep the machinery running smoothly. Regular upkeep includes cleaning, lubrication, and part replacement. Maintenance costs can vary, but budgeting around $1,000 to $2,000 annually is common.

Unexpected repairs can add to the costs. Always have a reserve fund for such incidents. Proper maintenance extends the life of the machinery, ensuring consistent production quality.

Quality Control

Quality control is a crucial step in producing a baseball glove. This stage ensures that each glove meets high standards. It involves several processes including inspection, testing, and adjustments. Let’s dive into each of these steps.

Inspection

The first step in quality control is inspection. Workers carefully examine each glove for defects. They check the stitching, leather quality, and overall construction. Each part of the glove is inspected for any flaws. This ensures that only the best gloves move to the next stage. A detailed inspection is vital. It helps catch any issues early in the process.

Testing

After inspection, the gloves undergo testing. This step checks the glove’s performance. Workers test the glove’s flexibility and durability. They also assess how well it catches and holds a baseball. Different tests simulate real game conditions. The aim is to ensure the glove performs well on the field. Only gloves that pass these tests move forward.

Adjustments

If a glove does not pass the tests, it needs adjustments. This can involve fixing the stitching or reshaping the leather. Workers make these adjustments to meet the quality standards. Sometimes, small changes can make a big difference. Each glove is adjusted until it meets the required standards. This ensures every glove is game-ready.

Credit: thehittingvault.com

Packaging And Shipping

Packaging and Shipping are crucial components of producing a baseball glove. These steps ensure the product reaches the customer in perfect condition. Packaging materials, shipping costs, and logistics each play a vital role in this process.

Packaging Materials

To protect the baseball gloves, manufacturers use various packaging materials. These materials include:

- Cardboard boxes: Durable and recyclable.

- Bubble wrap: Adds cushioning and prevents damage.

- Plastic bags: Provides an extra layer of protection against moisture.

Using quality packaging materials ensures the glove remains undamaged during transit. This care helps in maintaining customer satisfaction and reducing return rates.

Shipping Costs

Shipping costs can vary based on several factors:

| Factor | Impact on Cost |

|---|---|

| Distance | Longer distances increase shipping costs. |

| Weight | Heavier packages cost more to ship. |

| Shipping Method | Express shipping is more expensive than standard shipping. |

Choosing the right shipping method can balance cost and delivery speed. Many companies offer different shipping options to meet customer needs.

Logistics

Logistics involve planning and executing the movement of goods from the manufacturer to the customer. Key elements include:

- Warehousing: Storing the baseball gloves before shipment.

- Inventory Management: Keeping track of stock levels.

- Transportation: Moving the gloves from the warehouse to the customer.

Efficient logistics ensure timely delivery and reduce shipping costs. Companies often use advanced software to manage logistics effectively. This technology helps in tracking shipments and optimizing delivery routes.

Overhead Expenses

Understanding the overhead expenses is crucial in calculating the cost of producing a baseball glove. These expenses include utilities, rent, and administrative costs. Each of these factors contributes to the final price of the product. Let’s take a closer look at each.

Utilities

Utilities cover electricity, water, and gas. These are essential for running the factory. The machines that sew the gloves need power. Workers also need a comfortable environment to work in. Heating or cooling the factory adds to the cost. Efficient use of utilities can help save money.

Rent

Rent is another significant overhead expense. Factories need large spaces to operate. The cost of renting a factory varies by location. In cities, rent is usually higher. Rural areas might be cheaper but have other costs. The rent must be factored into the glove’s final price.

Administrative Costs

Administrative costs include salaries for office staff. This also covers office supplies and software. Managing orders and customer service also add to these costs. Efficient administration helps in smooth production. Good management ensures timely delivery and quality control.

Market Factors

Market factors play a significant role in the cost of producing a baseball glove. These factors include demand, competition, and pricing strategy. Understanding these elements can help manufacturers make informed decisions and remain competitive.

Demand

The demand for baseball gloves fluctuates based on various factors. Seasonal trends, such as the start of the baseball season, can cause a spike in demand. In contrast, the off-season may see reduced interest. Additionally, market demand can be affected by the popularity of baseball in different regions. Manufacturers must monitor these trends to adjust production levels accordingly.

Competition

Competition in the baseball glove market is intense. Multiple brands strive to offer the best quality and prices. This rivalry can drive innovation but also impact production costs. Companies need to stay ahead of competitors by investing in research and development. They must also consider their competitors’ pricing and promotional strategies.

Pricing Strategy

A well-planned pricing strategy is essential for balancing costs and profits. Manufacturers may use cost-based pricing, setting prices based on production costs plus a markup. Value-based pricing, which considers the perceived value to the customer, is another approach. Offering different glove models at various price points can attract a broader audience. Special promotions and discounts can also influence the overall pricing strategy.

| Market Factor | Impact on Cost |

|---|---|

| Demand | Influences production volume; higher demand can lower per unit costs. |

| Competition | Encourages innovation; can increase costs due to R&D investments. |

| Pricing Strategy | Impacts profit margins; requires balancing cost and customer value. |

Frequently Asked Questions

What Factors Affect Baseball Glove Production Costs?

The cost is influenced by materials, labor, design complexity, and brand reputation. Quality leather is more expensive. Skilled craftsmanship also increases costs.

Are Custom Baseball Gloves More Expensive?

Yes, custom gloves typically cost more due to personalized design, specific materials, and unique features. These factors increase production expenses.

How Much Does Leather Quality Impact Cost?

High-quality leather significantly raises production costs. Premium leather ensures durability and better performance, justifying the higher price.

Do Brand Names Affect Glove Prices?

Yes, well-known brands often charge more. They invest in quality materials, skilled labor, and brand prestige, raising costs.

Conclusion

Producing a baseball glove involves various costs. Materials like leather and laces matter. Labor costs add up too. Quality affects the final price significantly. Customization can raise expenses. Understanding these factors helps in making better choices. Research and compare before purchasing.

Always seek value for your money. A good glove enhances your game experience. Happy playing!

I’m Darrell Boyd, and I live and breathe baseball. As an ardent aficionado of the game, I have established myself as a respected figure in the baseball community through my dedicated blog and insightful contributions to the sport.

Through my blog, I strive to offer comprehensive baseball guides, tips, and tricks that cater to players of all skill levels. Additionally, I provide detailed reviews of crucial baseball products and elements, giving my readers an expert’s perspective on what truly matters in the world of baseball.

With a deep understanding of the sport’s technical intricacies and strategic nuances, I go beyond surface-level analysis, delving into the finer points that define successful gameplay. My meticulous attention to detail and unwavering commitment to excellence have made me a trusted resource for players, coaches, and fans looking to deepen their knowledge and appreciation of the game.

I am dedicated to fostering a thriving baseball culture and am passionate about sharing my wealth of insights with a growing community of fellow enthusiasts. My mission is to continue inspiring and educating others, leaving a lasting impact on the sport that resonates with millions across the globe.