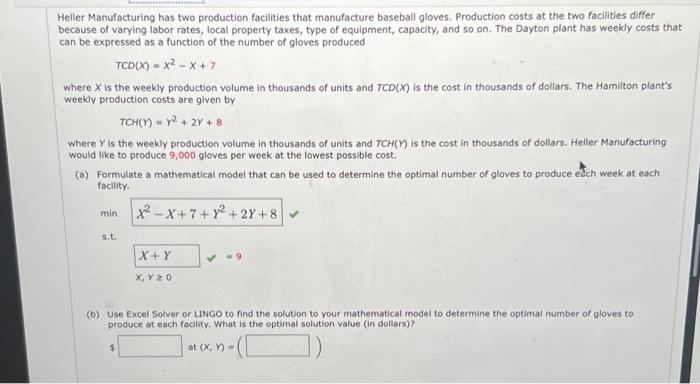

The cost to manufacture a baseball glove varies. Factors like materials, labor, and production scale influence the price.

Manufacturing a baseball glove involves several steps. Each step, from cutting leather to stitching, requires time and skill. The type of leather used, whether synthetic or genuine, affects the cost. Labor costs depend on the location of the manufacturing facility.

For instance, gloves made in countries with lower labor costs are cheaper. The scale of production also matters; larger batches reduce costs per glove. Understanding these elements helps in estimating the overall cost. This blog will break down these factors to give you a clearer picture of what goes into making a baseball glove.

Credit: www.yanrefitness.com

Materials Required

Understanding the materials required for manufacturing a baseball glove is crucial. The cost largely depends on the quality and type of materials used. Different materials impact the durability, flexibility, and overall performance of the glove.

Leather Types

Leather is the primary material for baseball gloves. There are several types of leather used, each affecting the glove’s cost. Full-grain leather is the highest quality and most expensive. It offers excellent durability and a great feel.

Top-grain leather is slightly less expensive but still provides good quality. It is more pliable than full-grain. Split leather is the cheapest option. It is less durable and used in lower-end gloves.

Lacing Materials

High-quality lacing is essential for a strong, durable glove. Most gloves use leather laces. These laces are strong and can withstand the stress of gameplay. Higher-end gloves use full-grain leather laces.

Synthetic laces are another option. They are cheaper but less durable. Synthetic laces are often found in youth or beginner gloves. Choosing the right lacing material impacts both cost and performance.

Labor Costs

Labor costs play a significant role in the overall expense of manufacturing a baseball glove. These costs include the wages paid to the workers involved in the production process. Labor costs can vary based on the location of the manufacturing facility and the skill level of the workers.

Skilled Labor

Creating a high-quality baseball glove requires skilled labor. Workers need to have experience in leatherworking. They must be able to cut, stitch, and assemble the gloves precisely. Skilled workers ensure each glove meets specific standards. Their expertise contributes to the glove’s durability and performance.

Manufacturing Time

The time it takes to manufacture a baseball glove also affects labor costs. From start to finish, it can take several hours to complete one glove. The process includes cutting leather, stitching pieces together, and adding finishing touches. Longer manufacturing times mean higher labor costs. Efficient processes help reduce time but still require skilled hands.

Manufacturing Process

Understanding the manufacturing process of a baseball glove helps to appreciate its cost. Each step involves skill and precision. Let’s break down the main stages that contribute to the final price.

Cutting And Shaping

The first step is selecting high-quality leather. This material is crucial for durability and comfort. Workers use templates to cut the leather into pieces. These pieces form different parts of the glove. Each cut must be accurate. This ensures the glove fits well and lasts long.

After cutting, the leather pieces are shaped. This involves stretching and molding the leather. The goal is to create a natural curve. This helps the glove hold its shape over time. Skilled hands and attention to detail are essential in this stage.

Stitching And Assembly

The cut and shaped leather pieces are stitched together. This step requires precision. Workers use strong thread to stitch the pieces. The stitching pattern is unique. It adds strength and flexibility to the glove. Misaligned stitches can affect the glove’s performance.

After stitching, the glove undergoes assembly. Workers attach additional parts like the webbing and padding. The webbing is important for catching the ball. Padding adds comfort and protection. Each part must be assembled correctly. This ensures the glove performs well during play.

Finally, the glove is inspected. Quality control checks ensure no defects. Only the best gloves make it to the store shelves. This thorough process explains why manufacturing a baseball glove is costly.

Overhead Expenses

Understanding the overhead expenses involved in manufacturing a baseball glove is crucial. Overhead expenses include costs that aren’t directly tied to production. These costs keep the factory running smoothly.

Factory Maintenance

Regular factory maintenance is essential to ensure production efficiency. This involves servicing machinery, repairing equipment, and keeping the facility clean. Maintenance prevents breakdowns that could halt production.

Consider these common maintenance tasks:

- Lubricating machines

- Replacing worn parts

- Cleaning work areas

These activities require skilled technicians and regular inspections. The costs for these services accumulate over time. On average, factory maintenance can cost thousands of dollars annually.

Utility Costs

Utility costs are another significant overhead expense. These include electricity, water, and gas. Manufacturing baseball gloves requires consistent power for machines and adequate lighting.

Let’s look at a typical breakdown:

| Utility | Monthly Cost |

|---|---|

| Electricity | $5,000 |

| Water | $1,000 |

| Gas | $500 |

Utility costs vary based on factory size and location. Efficient energy use can help control these expenses. Investing in energy-saving equipment pays off in the long run.

Quality Control

Quality control is crucial in manufacturing baseball gloves. It ensures every glove meets high standards. This process involves several steps, including inspection procedures and testing methods. Let’s dive into these essential components.

Inspection Procedures

Inspection procedures play a vital role in quality control. Inspectors check every glove meticulously. They look for defects in stitching, leather quality, and overall craftsmanship. A thorough inspection guarantees a durable and comfortable glove.

Inspectors follow a checklist during their evaluations:

- Stitching integrity

- Leather texture and suppleness

- Size and shape consistency

- Color uniformity

Each glove must pass all these criteria to proceed to the next stage. This step ensures only the best products reach the market.

Testing Methods

Testing methods further ensure the glove’s quality. These tests measure the glove’s performance under different conditions. For instance, they assess how well the glove absorbs impact.

Common testing methods include:

- Impact tests to simulate catching a ball

- Flexibility tests to ensure ease of movement

- Durability tests to check wear and tear resistance

- Moisture resistance tests to evaluate performance in wet conditions

These tests ensure the glove performs well in actual use. A glove that passes all tests is ready for players.

Quality control involves both inspection and testing. These steps ensure every baseball glove meets high standards. This attention to detail enhances the player’s experience and safety.

Credit: www.chegg.com

Packaging And Shipping

Packaging and shipping are crucial steps in manufacturing a baseball glove. These steps ensure the product reaches the buyer in perfect condition. They also contribute to the overall cost. Let’s break down the packaging and shipping expenses.

Packaging Materials

High-quality packaging materials protect the baseball glove during transit. Manufacturers often use sturdy boxes and bubble wrap. These materials keep the glove safe from damage. Quality packaging also enhances customer experience. The cost of packaging materials varies. It depends on the quality and quantity used.

Transportation Costs

Transportation costs are another significant expense. Shipping baseball gloves involves several modes of transport. It can include trucks, ships, and planes. Each mode has its own cost structure. Distance and speed of delivery also affect the cost. Faster shipping methods are generally more expensive.

To manage costs, manufacturers often choose bulk shipping. This option reduces the per-unit cost of shipping. Efficient logistics planning is essential. It helps in reducing transportation costs and ensuring timely delivery.

Cost Variability

The cost to manufacture a baseball glove can vary greatly. Several factors influence this variability, including economies of scale and customization options.

Economies Of Scale

Manufacturing costs can decrease when producing baseball gloves in large quantities. This is known as economies of scale. Larger orders allow manufacturers to buy raw materials in bulk, often at a discounted rate. Here is a simple breakdown:

- Materials: Leather, padding, stitching

- Labor: Skilled workers, factory overheads

- Machinery: Maintenance, utility costs

For example, buying leather for 100 gloves costs less per unit than for 10 gloves. This bulk purchasing reduces the overall cost per glove.

Customization Options

Customization options can significantly impact the manufacturing cost. A custom glove often requires more labor and specialized materials. Below are common customization options:

- Personalized stitching (name, logo)

- Specialized leather (different colors, textures)

- Unique designs or patterns

These custom features increase the time and cost of production. A table below shows a simple comparison:

| Customization | Cost Increase |

|---|---|

| Personalized stitching | 10% |

| Specialized leather | 15% |

| Unique designs | 20% |

Custom gloves are often more expensive. Yet, they offer unique features that standard gloves do not.

Credit: www.yanrefitness.com

Market Pricing

Understanding the market pricing of a baseball glove is crucial. This helps in making informed decisions. Knowing this ensures you are getting value for your money. Let’s explore the factors that impact market pricing.

Retail Markup

Retailers often mark up the price of baseball gloves. They do this to cover costs and make a profit. The markup can range from 50% to 100%. This means a glove that costs $50 to make might sell for $100. Retailers need to cover expenses like rent, salaries, and marketing. So, the final price you pay includes these costs too.

Competitor Pricing

Competitor pricing also plays a role in market pricing. Companies keep an eye on their rivals. They adjust their prices to stay competitive. If one brand lowers its price, others might follow. This keeps the market balanced. It ensures customers have multiple options. Competitive pricing benefits consumers. It helps them find quality gloves at fair prices.

Frequently Asked Questions

What Affects The Cost Of Manufacturing Baseball Gloves?

The cost is influenced by materials, labor, and manufacturing location. High-quality leather and skilled labor increase costs. Automation can reduce expenses.

How Much Does Leather Quality Impact Cost?

Premium leather significantly increases manufacturing costs. It ensures durability and better performance. Lower quality leather reduces costs but affects glove quality.

Is Automation Used In Glove Manufacturing?

Yes, automation is used to streamline production. It reduces labor costs and improves efficiency. However, some parts still require manual craftsmanship.

Where Are Baseball Gloves Commonly Manufactured?

Baseball gloves are commonly manufactured in countries like China, Vietnam, and the Philippines. Labor costs are lower in these regions.

Conclusion

Understanding the costs of manufacturing a baseball glove helps you make better decisions. From materials to labor, each factor impacts the final price. Comparing different brands and production methods can save money. Quality often comes at a higher cost, but it lasts longer.

Always balance your budget with the need for durability and comfort. Now you have a clear idea of what influences baseball glove costs. Happy shopping!

I’m Darrell Boyd, and I live and breathe baseball. As an ardent aficionado of the game, I have established myself as a respected figure in the baseball community through my dedicated blog and insightful contributions to the sport.

Through my blog, I strive to offer comprehensive baseball guides, tips, and tricks that cater to players of all skill levels. Additionally, I provide detailed reviews of crucial baseball products and elements, giving my readers an expert’s perspective on what truly matters in the world of baseball.

With a deep understanding of the sport’s technical intricacies and strategic nuances, I go beyond surface-level analysis, delving into the finer points that define successful gameplay. My meticulous attention to detail and unwavering commitment to excellence have made me a trusted resource for players, coaches, and fans looking to deepen their knowledge and appreciation of the game.

I am dedicated to fostering a thriving baseball culture and am passionate about sharing my wealth of insights with a growing community of fellow enthusiasts. My mission is to continue inspiring and educating others, leaving a lasting impact on the sport that resonates with millions across the globe.